Cell Blocks

Cell Blocks

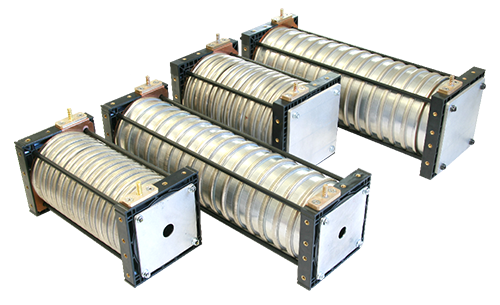

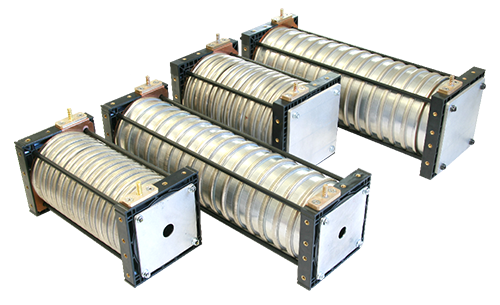

Rolled-Ribbon cells create stacked-cell-blocks that deliver superior performance.

Unlike cylindrical, pouch, and prismatic cells, Rolled-Ribbon cells have large terminal surfaces that provide low electrical and thermal resistances. This is essential for high-power battery systems. The Rolled-Ribbon cell design also enables the construction of stacked-cell-blocks that are “tough-as-nails”. Stacked-cell-blocks do not require welding, so cells within the cell blocks can be replaced and they can be repurposed. Rolled-Ribbon cell blocks are flexible, modular, and scalable. They can be configured in stacks of 4 to 72 cells per column block. Cell blocks can have from 1 to 4 interconnected columns per block. Rolled-Ribbon cell blocks support thermal management methods such as passive convection, active convection, and liquid conduction (with or without phase change material).

Rolled-Ribbon cells and batteries are ideal for high-power high-capacity battery applications such as Directed Energy Weapons (DEW), high-power hybrid drivetrains (large trucks, buses, etc.), heavy-duty electric vehicles and equipment (military, construction, industrial, utility, commercial, etc.), microgrids, grid support systems (load shifting, peak shaving, etc.) and high-power UPS and hybrid power systems (standby, power bridging, fuel economizing, etc.).

Features-Advantages:

High-Power (>1C)

High-Capacity (>10Ah)

Low Electrical and Thermal Resistance

Stacked-Cell-Block Design

No Welding

Replace Cells

Repurpose Cells

Flexible, Modular, Scalable

136mm, 165mm Diameter Cells

1 to 4 Columns/Cell Block

4 to 72 "XXX-15" Cells/Column

4 to 36 "XXX-28" Cells/Column

Rugged, Durable ("tough-as-nails")

Thermal Management Options

Passive Convection

Active Convection

Liquid Conduction

Phase Change Material (PCM)

Applications:

High-Power Hybrid Drivetrains (HEV)

Heavy-Duty Electric Vehicles and Equipment (military, construction, industrial, utility, commercial)

Microgrids – Grid Support Systems

Resilience

Load Shifting, Peak Shaving

High-Power UPS and Hybrid Power Systems

Standby Power, Power Bridging

Fuel Economizing

Directed Energy Weapons (HEL, RF, DPM)